+86 10 5248 4022

+86 18518927929

Dec. 21, 2023

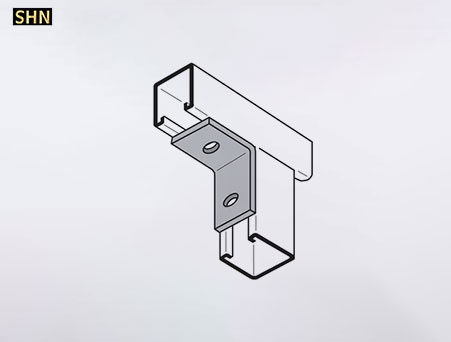

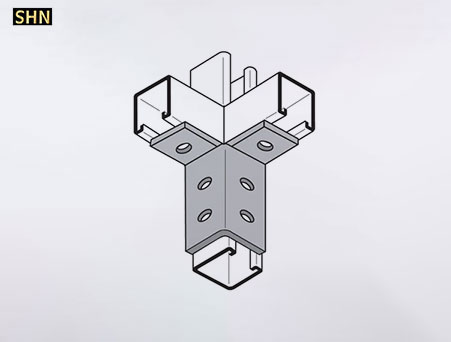

Angle fittings are an essential component of channel strut systems. They are used to join two strut channels at a desired angle, providing stability and support. These fittings are available in various materials such as pre-galvanized (GI), hot-dip galvanized (HG), plain (PL), stainless steel (SS), and aluminum (EA). The choice of material depends on the specific application requirements, such as corrosion resistance or aesthetic appeal.

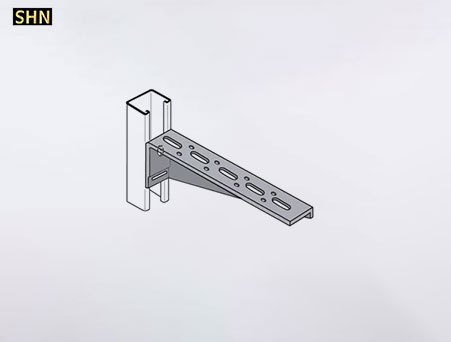

Shelf brackets and braces are used to support shelves or other flat surfaces in channel strut systems. These accessories come in different sizes and materials, including pre-galvanized (GI), hot-dip galvanized (HG), plain (PL), stainless steel (SS), and aluminum (EA). The selection of the appropriate bracket or brace depends on the load-bearing capacity and the desired aesthetic appearance.

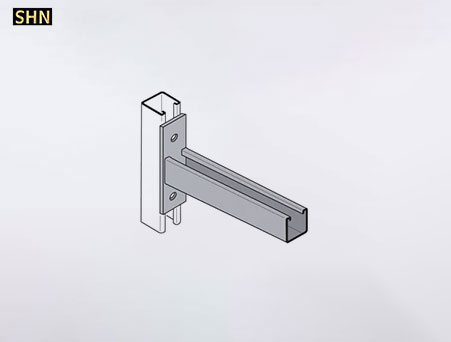

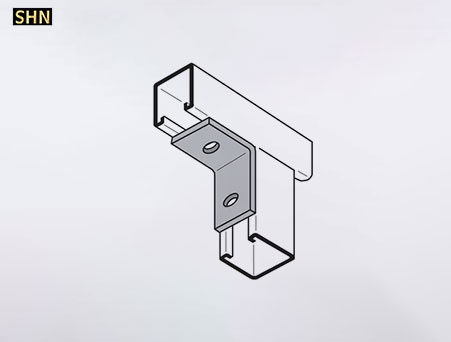

Channel brackets are designed to provide additional support to the strut channels. They are used to secure the channels to walls, ceilings, or other structures. These brackets are available in various materials, including pre-galvanized (GI), hot-dip galvanized (HG), plain (PL), stainless steel (SS), and aluminum (EA). The choice of material depends on the application requirements, such as corrosion resistance or durability.

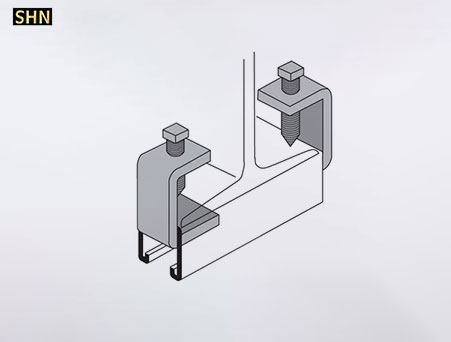

Beam clamps are used to attach strut channels to beams or other structural members. They provide a secure connection and allow for adjustability. Beam clamps are available in different materials, such as pre-galvanized (GI), hot-dip galvanized (HG), plain (PL), stainless steel (SS), and aluminum (EA). The material selection depends on factors such as load capacity, environmental conditions, and desired aesthetics.

Clevis fittings are used to connect strut channels to other components, such as rods or hangers. They provide a strong and adjustable connection. Clevis fittings are available in various materials, including pre-galvanized (GI), hot-dip galvanized (HG), plain (PL), stainless steel (SS), and aluminum (EA). The choice of material depends on factors such as corrosion resistance, load capacity, and the specific application requirements.

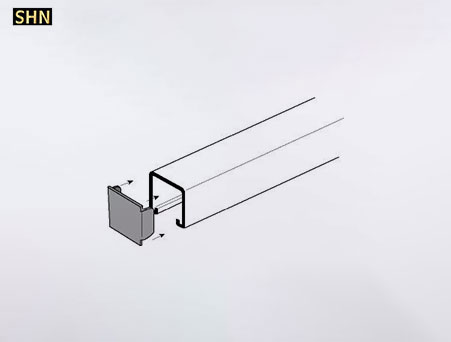

Strut channel end caps are used to close off the ends of strut channels, providing a finished appearance and protecting the channel from dirt and debris. These end caps are available in different materials, including pre-galvanized (GI), hot-dip galvanized (HG), plain (PL), stainless steel (SS), and aluminum (EA). The material selection depends on factors such as corrosion resistance, aesthetics, and the specific application environment.

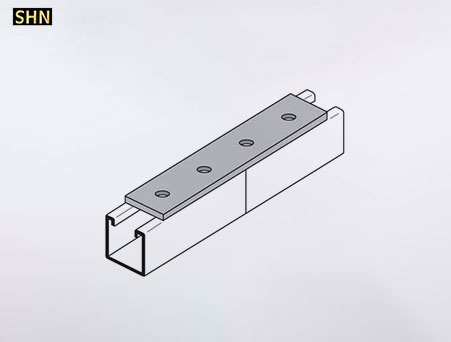

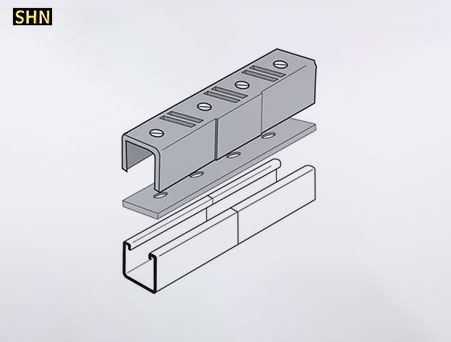

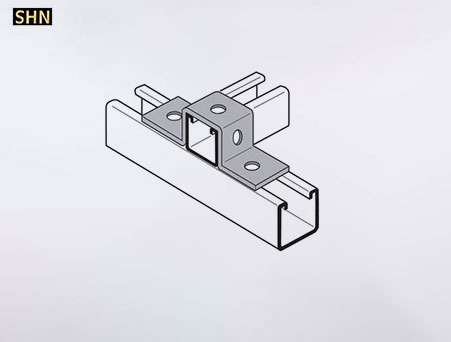

Flat fittings are used to create flat connections between strut channels or other components. They provide stability and support in various applications. Flat fittings are available in different materials, including pre-galvanized (GI), hot-dip galvanized (HG), plain (PL), stainless steel (SS), and aluminum (EA). The choice of material depends on factors such as load capacity, corrosion resistance, and the desired aesthetic appearance.

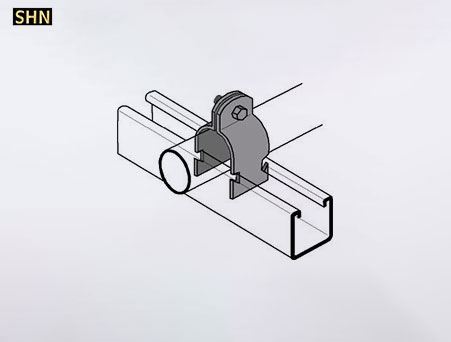

Channel hangers and electrical accessories are used to support and secure electrical components, such as conduits or cables, within the strut channels. These accessories are available in various materials, including pre-galvanized (GI), hot-dip galvanized (HG), plain (PL), stainless steel (SS), and aluminum (EA). The material selection depends on factors such as electrical conductivity, corrosion resistance, and the specific application requirements.

Pipe straps and clamps are used to secure pipes or tubes within the strut channels. They provide stability and prevent movement or vibration. Pipe straps and clamps are available in different materials, including pre-galvanized (GI), hot-dip galvanized (HG), plain (PL), stainless steel (SS), and aluminum (EA). The choice of material depends on factors such as pipe diameter, load capacity, and environmental conditions.

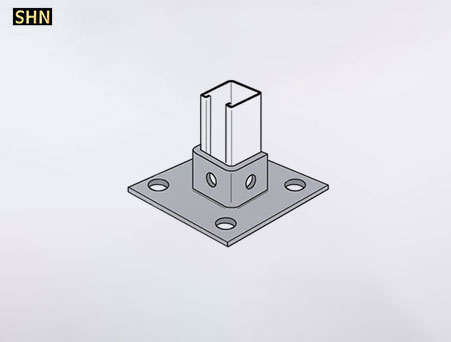

Channel post bases are used to provide a stable and secure foundation for channel struts. They are typically used in construction projects to support structures such as signs, fences, or solar panels. Channel post bases are available in various materials, including pre-galvanized (GI), hot-dip galvanized (HG), plain (PL), stainless steel (SS), and aluminum (EA). The material selection depends on factors such as load capacity, corrosion resistance, and the specific application requirements.

Z and U-shaped fittings are used to create connections between strut channels at different angles or orientations. These fittings provide flexibility and allow for adjustable connections. Z and U-shaped fittings are available in various materials, including pre-galvanized (GI), hot-dip galvanized (HG), plain (PL), stainless steel (SS), and aluminum (EA). The choice of material depends on factors such as load capacity, corrosion resistance, and the desired aesthetic appearance.

Wing fittings are used to create connections between strut channels and other components, such as brackets or braces. They provide a secure and adjustable connection. Wing fittings are available in different materials, including pre-galvanized (GI), hot-dip galvanized (HG), plain (PL), stainless steel (SS), and aluminum (EA). The material selection depends on factors such as load capacity, corrosion resistance, and the specific application requirements.

Previous 2 Hole Pipe Clamps

Channel Strut Manufacturers & Suppliers

Dec. 20, 2023316 Stainless Steel Strut Channels

Dec. 19, 2023Leave Message

Write down your urgent needs to get free samples, and to check our stocks

Copyright © SS&HN INDUSTRY GROUP Ltd. All Rights Reserved | Sitemap | Powered by